VIP and nickel

Climate change is making us strive to become less dependent on fossil fuels. Non-carbon dioxide emitting fuels such as hydrogen and ammonia provide alternatives. And as we transition towards non-fossil fuels, liquefied natural gas has proven to be a working intermediate alternative to oil as an energy source to produce electricity or heating.

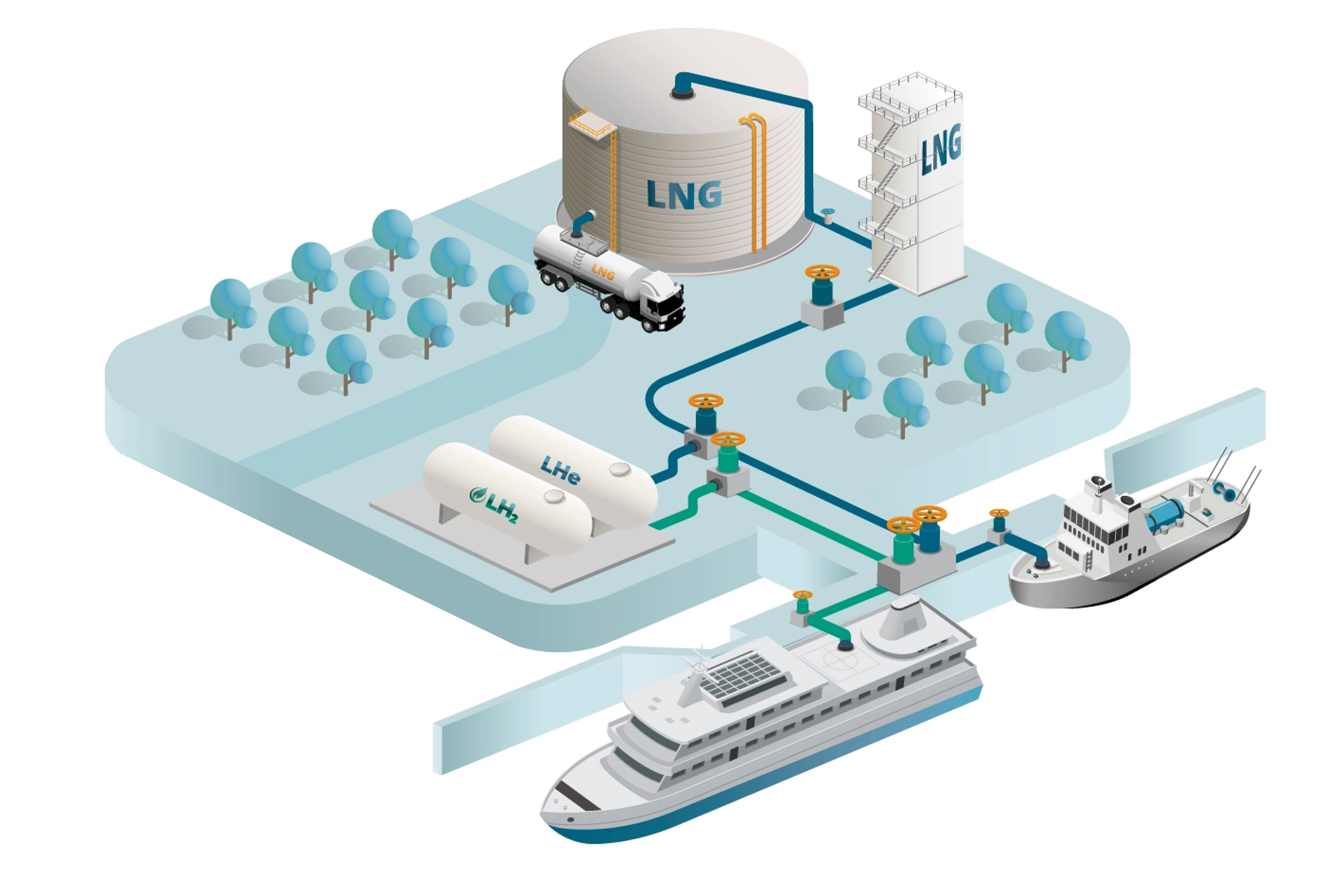

The production, transportation and use of these alternative energy carriers however requires liquefying them at some point in the process.

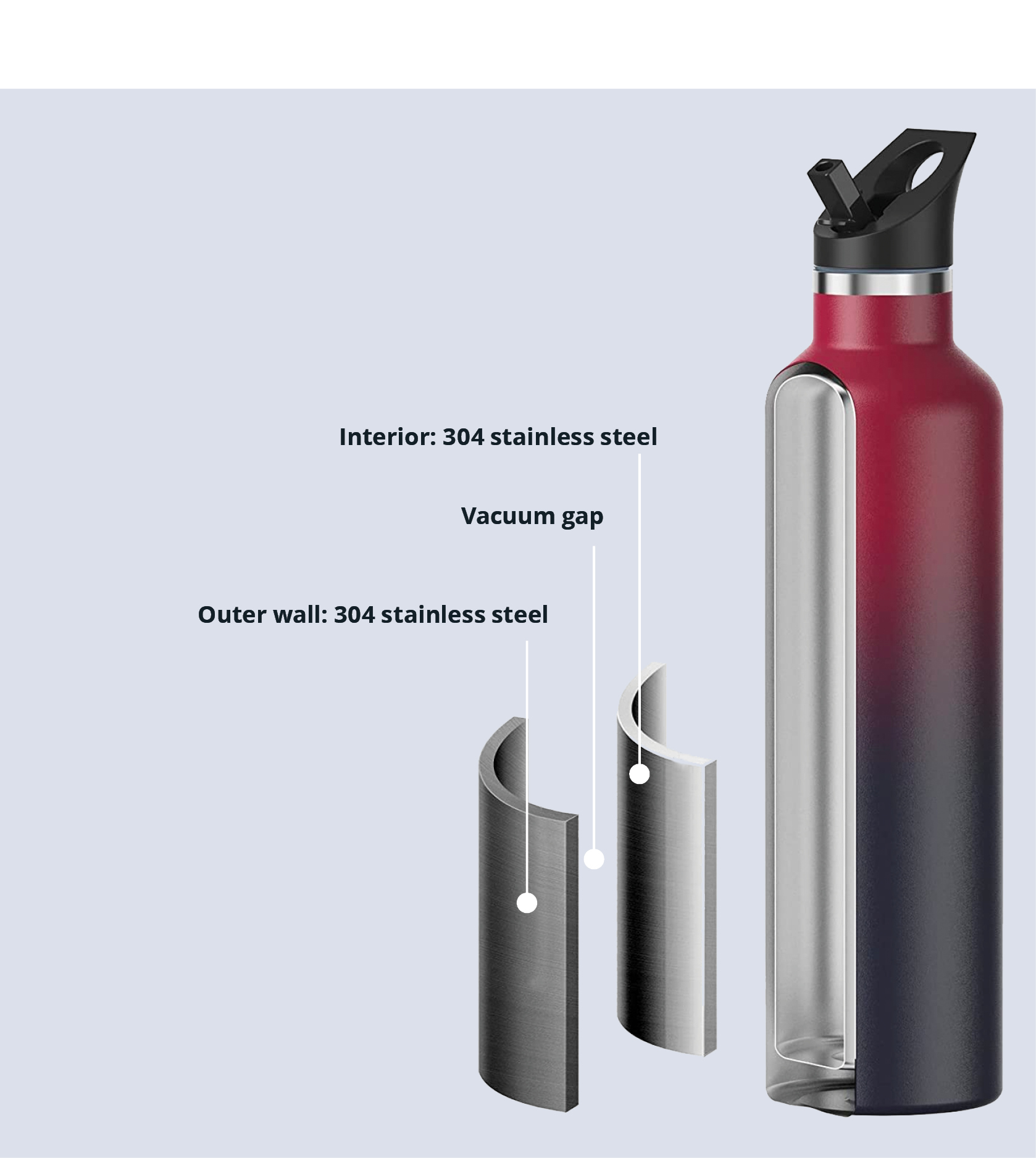

In the case of liquefied natural gas (LNG), this happens at very low temperatures. Care must be taken to ensure that the cooled and liquefied gases stay liquid as long required to store and supply them. For this to work requires proper insulation of the liquefied gases from the environment.

This is where nickel comes into the picture. Nickel-containing stainless steels have many attractive properties. Above all, they are ductile and resilient, even at low temperatures, which makes them the materials of choice to efficiently transport liquefied gases through piping networks.